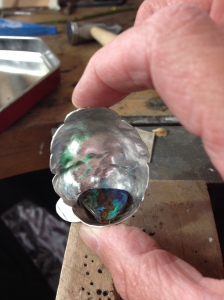

I have rather lovely Boulder Opal which was brought back from Australia for me. This isn’t the best picture of the Opal. It’s much more blue.

It reminds me of a pool of water and I would like to capture the natural feel of the stone. I want the piece to reflect the colours of the opal but at the same time cocoon it and keep it safe. Those that know me will understand my reluctance to create an “organic’ piece of jewellery. I have seen too many pieces which are called ‘organic’ to cover up shoddy workmanship and poor finishing. I aim to have a finished piece that is neither of those things!

I decided I wanted to place the opal in an eggshell. It would look like a little pool of water had gathered in the eggshell once the chick had flown.

To start with I had to make the eggshell. I took a sheet of 0.8mm silver and cut an egg shape with a handle out of it.

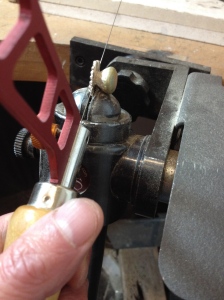

I planned on using a ‘spoon stake’ to form the egg. I secured the stake in the big vice, laid the silver over the top and started hammering it. I started around the edges and then moved into the centre. I pretty soon discovered that the ‘handle’ was not only unnecessary but a blinking nuisance! I cut it off! You can see the shape starting to form.

I planned on using a ‘spoon stake’ to form the egg. I secured the stake in the big vice, laid the silver over the top and started hammering it. I started around the edges and then moved into the centre. I pretty soon discovered that the ‘handle’ was not only unnecessary but a blinking nuisance! I cut it off! You can see the shape starting to form.

Before too long the metal became really hard and difficult to work so I annealed it. Annealing is the process of softening the metal using heat. The silver is heated up to a straw colour and then pickled in weak sulphuric acid solution to remove the traces of copper oxide that form on the surface

Then back to the shaping, more hammering, more annealing, more pickling. Oh, and cups of tea while pickling.

Actually it’s too big.and still too shallow. I need to make it smaller and deeper. I didn’t really know how much the metal would stretch with forming so I erred on the side of caution. Drew a line using a black sharpie and the sawed off the spare.

I used the doming block to deepen the bottom curve and then drew lines to resemble the cracked edges of the shell. I plan to engrave the ‘cracks’ in the back of the shell when it’s finished.

I think the shaping’s done.. Time to make and add the bail. I cut a short strip of 1mm sheet and bent it then soldered it.

I positioned the bail on the egg and soldered it in place – the wrong place! It leans forward too much. I need to do it again!

To remove the bail I held the bail itself in a the third hand. (Free standing tweezers) and heated it up. The solder ran and the egg dropped off. I repositioned it further up the egg.

That’s better, it hangs nicely now. Just need to make the bezel to set the opal in. This was the point when i realised that the stone was really thick and didn’t lay flat. Should have spotted this before. Here’s the stone, side view laying on a flat file. You can clearly see the curve on the lower surface and the thickness.Since the opal surface itself is actually quite thin I figured I could remove a lot of the brown rock at the back without harming the stone. I found, by trial and error, the best way was to rub it over coarse sandpaper. This had the effect of flattening the base and thinning the stone.

At this point I wrapped fine silver bezel strip round the stone, cut the strip, soldered it and formed it into the correct shape. I needed to do some more thinning of the stone to get it to look right.

Ok, now I needed to figure out a way to get the opal to sit in the egg so it would reflect off the back and appear like a pool. The egg still wasn’t really deep enough at the bottom so I needed to do more shaping. This time I used my lead block and a small hammer. I think this is called a chasing hammer. I made the lead block last summer by melting offcuts of lead flashing into an old loaf tin. I can assure you the loaf tin is no longer used for loaves!

Lead is softer than silver, when the silver is struck it deforms down into the lead. This is the reverse of the shaping I did over the stake. I was able to deepen the base of the egg sufficiently to hold the opal in the bottom. It’s really important to do lots of hand and tool and egg washing throughout the entire process. I wouldn’t want to accidentally munch a biscuit laced with lead.

Finally got it to the right shape. I did a lot of admiring at this stage, just resting the opal in the egg and taking photos!

All this was well and good but I still hadn’t come up with a way to set the opal that wouldn’t leave a gap around the edge. I decided to make a tight fitting little shelf that the bezel would sit on. Again, more head scratching. The inside of the egg wasn’t regular – because of this darned ‘organic’ concept and I was really stumped.

Finally – inspiration! I would put some Fimo modelling clay in the base, press the opal into it, remove the stone and then bake it. My theory was that the clay would form to the egg and I could then use it as a template to cut out a little shelf of silver.

Here it is after baking. I need to trim off the excess and then I should have my template.

After sanding down the Fimo clay I positioned it in the egg. It seemed to fit quite well. Only little gap.

I sat the opal on the shelf to see if it looked ok. Not bad.

Now I needed to cut out a little sheet of silver to replace the Fimo. I put the Fimo shape on a sheet and drew round it. I made sure I marked which side was which otherwise I would be fiddling around for ages trying to work out which way up it went.

It fitted reasonably well but wobbled around a lot sliding up and down and left and right. I just couldn’t seem to get it so there wasn’t a gap around the edge.

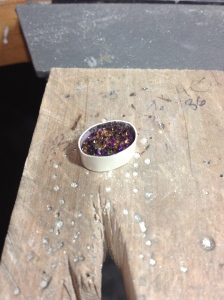

Time to make the bezel that will secure the opal. I wrapped fine silver snugly around the stone to hold it in place.

I wanted to get the bezel fitted to stabilise the little shelf. I felt it was flexing as I tried to position it. I put the bezel in place on the shelf and soldered it. That went ok!

Test the fit by putting the stone in the setting. I used dental floss to enable me to get it out again. I really did need the floss, it fitted VERY snugly and needed quite a yank to get it out. So much of a yank in fact that the opal shot out and vanished somewhere in the workshop.

That would be a hands and knees search. I finally found it underneath the recycling bags!

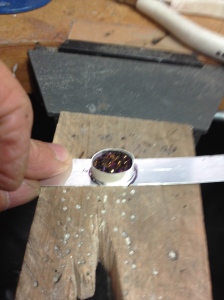

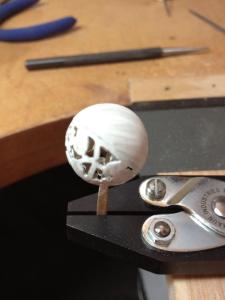

I kept trying to settle the shelf in the bottom of the egg but I just couldn’t get it to stay still. Eventually I admitted defeat and soldered a little peg on the bottom of the bezel and drilled a corresponding hole in the bottom of the egg

To solder the shelf in place I knew I would need a lot of heat to get the egg up to temperature I was worried that the bezel seams would run so I painted them with tippex. Tippex stops solder flowing and will have the effect of protecting the seams on the bezel.

I made a little ring of wire which I think will anchor the shelf into the egg.

Here it is after soldering.

After soldering I pickled the whole structure and then cut off the peg that was protruding from the bottom of the egg.

Just need to file off the excess solder from around the join. The I trial fitted the opal – using the old dental floss trick again.

Ok. the stone fitted. Now to polish it. Oh my days! the amount of fireplace was horrific. I polished and polished and polished! Then washed off the polish using an electric toothbrush and washing up liquid.

OK. Still covered in firescale, it needed MORE polishing. The big bench polisher was fine for the outside but I needed to use the pendant motor fitted with a mop for the inside. At this stage I was worrying that the action of polishing would damage the delicate bezel. I fitted the stone into the bezel to support it and covered it with a bit of masking tape to protect the surface.

It took forever and I got a very dirty face from all the polish flying around. I think you can tell from the look of triumph that I finally got it all done!

I wanted to make the back of the egg look as if it was cracked so I decided to use my newly acquired skill (Ha ha – laughs in frustration – engraving is, I believe, a dark art and my attempts cannot be in any way described as skillful)

I needed to support the egg while engraving so I used Polymorph. Polymorph is an amazing plastic which deforms with heat and the goes rock hard when cool. I fitted a warm lump onto the bench mate and pressed the egg into it. I could then use a graver to cut lines on the back that looked like cracks. Its not clear in the photos – sorry.

Finally I made a chain and a clasp and there we are. A little egg to hold an opal safe.